Occupational Health and Safety of Workers

Occupational health and safety

Various activities from construction to airport operations rely on employees and business partners, e.g., contractors and partners. Therefore, good occupational health and environmental management is extremely important and directly affects valuable organizational resources. Without good occupational health and safety, accidents causing injuries and loss of employees and contractors may occur. It may also indirectly affect customer service, and community, as well as violate the requirements of regulators, leading to violation of human rights regarding the right to life and safety.

Policy

AOT operates with responsibility for the occupational safety of the stakeholders. As a result, the Occupational Health, Safety, and Work Environment policy has been issued. The Safety and Occupational Health System Management manual including work safety regulations and manuals for contractors are used as guidelines for employees and all of AOT’s contractors, covering those at AOT’s airports and Head Office.

See more detail

Management Approaches

AOT prioritizes safe working environment in compliance with occupational health and safety principles in all 6 airports of AOT and the Head Office. This is the core principle of airport operations where all personnel working under AOT’s premises must comply with. Currently, Occupational Health and Safety Management System of AOT Head Office and all 6 airports have been certified by ISO 45001:2018 Standard. This management system will enable occupational health and safety management of AOT to achieve the safety and management of international standards.

See more detail

Duty and Responsibility

AOT requires 6 airports and its Head Office to set up the responsible persons for occupational health and safety with duties and responsibilities as follows:

See more detail

AOT’s Safety, Occupational Health and Work Environment Committee (SHE Committee) performs 11 duties and responsibilities as stipulated in the Ministerial Regulation on the Prescribing of Standard for the Administration and Management of Occupational Safety, Health, and Environment B.E.2549 (2006). The committee’s structure is composed of Chairman (appointed by the employer), Professional Safety Officer who acts as committee member and secretary, representatives of the employers at the executive level (appointed by the employer), and representatives of the employees from all levels (elected). The Committee meeting is held for at least once a month to acknowledge operation results and provide suggestions on occupational health measurements in order to continuously enhance management efficiency.

Standard Operation Procedure

AOT specified the Standard Operation Procedure as a guideline for the systematic operation of occupational health and safety and requires the operator to hold meetings with the human resources department with the Board of Directors to report the operational situation on a regular basis.

AOT’s Standard Operation Procedure covers the following topics

- Hazard identification and risk assessment

- Management of Harm from psychological and social factors at work

- Management of compliance with occupational health and safety laws and requirements

- Determination of objectives and plans for occupational health and safety

- Specification of competencies, training, and awareness

- Communication, engagement, and counseling

- Document and record control

- Practice control

- Change management

- Procurement and contractor control

- Emergency preparedness and response

- Monitoring of safety practice

- Monitoring, inspection, and assessment of occupational health and safety practice

- Management system evaluation

- Management system review by executives

- Accident and incident investigation

- Remediation and prevention

Overview of the Occupational Health,

Safety and Work Environment Management

Hazard Identification and Risk Assessment

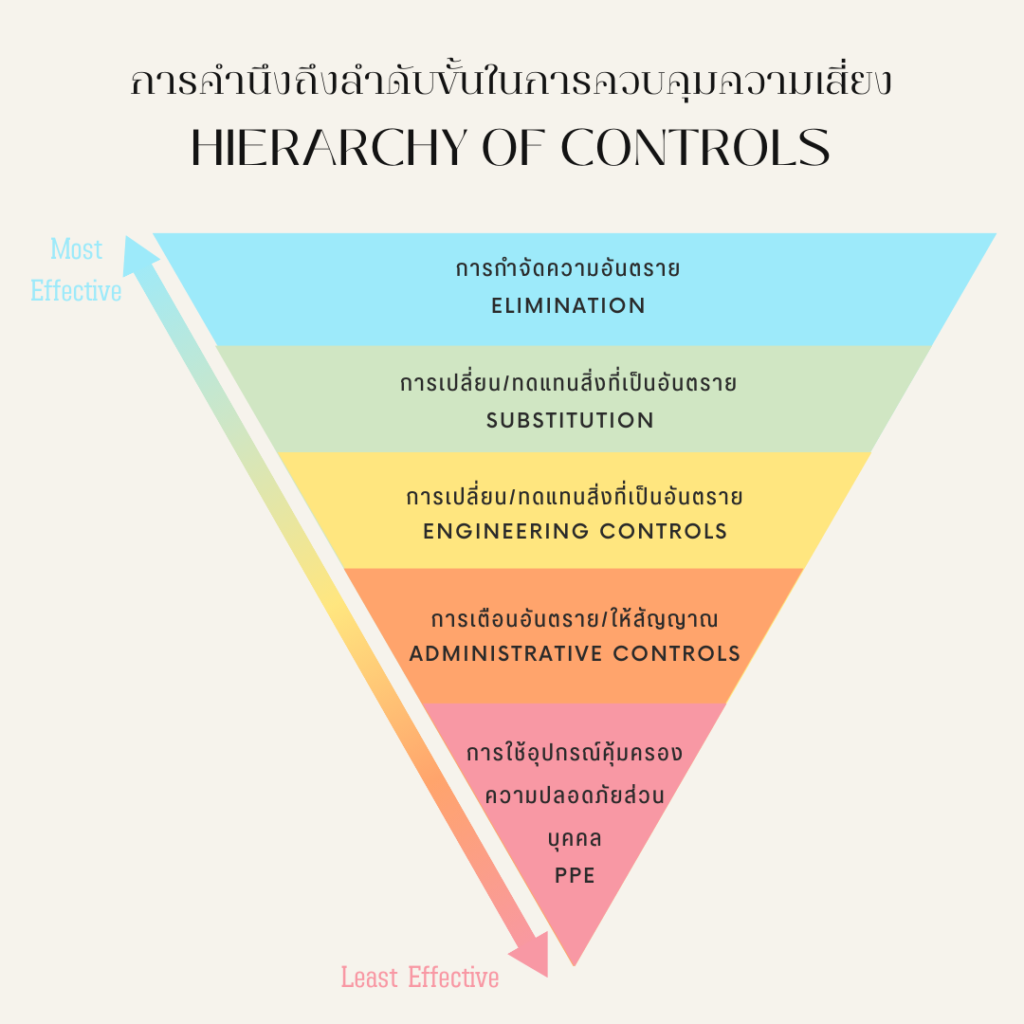

According to the planning requirement of the Occupational Health and Safety Management System Standard or ISO 45001:2018, AOT applies the hazard identification and risk assessment process in each activity and work environment. The process is regularly reviewed at least once a year by the assigned person of each department together with the safety officers. The result of which is reported to the Occupational Health and Safety System Management Committee and senior executives which shall be used to define the Hierarchy of Controls, as follows:

In the case of witnessing a hazardous work environment, the operator at all levels can participate in reporting the risks and concerns that arise at any time to the SHE Committee to assess and solve the situations. Reporting on hazardous incidents, risks and opportunities is considered as an operation for improvement, remediation, and development of the occupational health and safety management system.

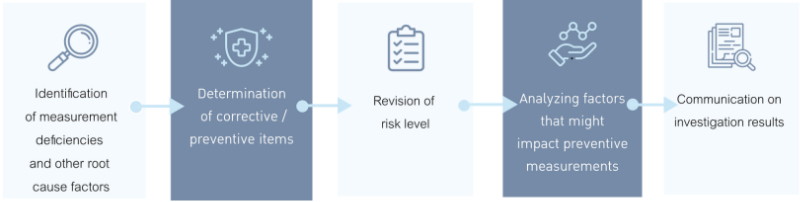

Incident Investigation

In case there is any occurrence of incidents, AOT would activate the investigation procedures, as follows:

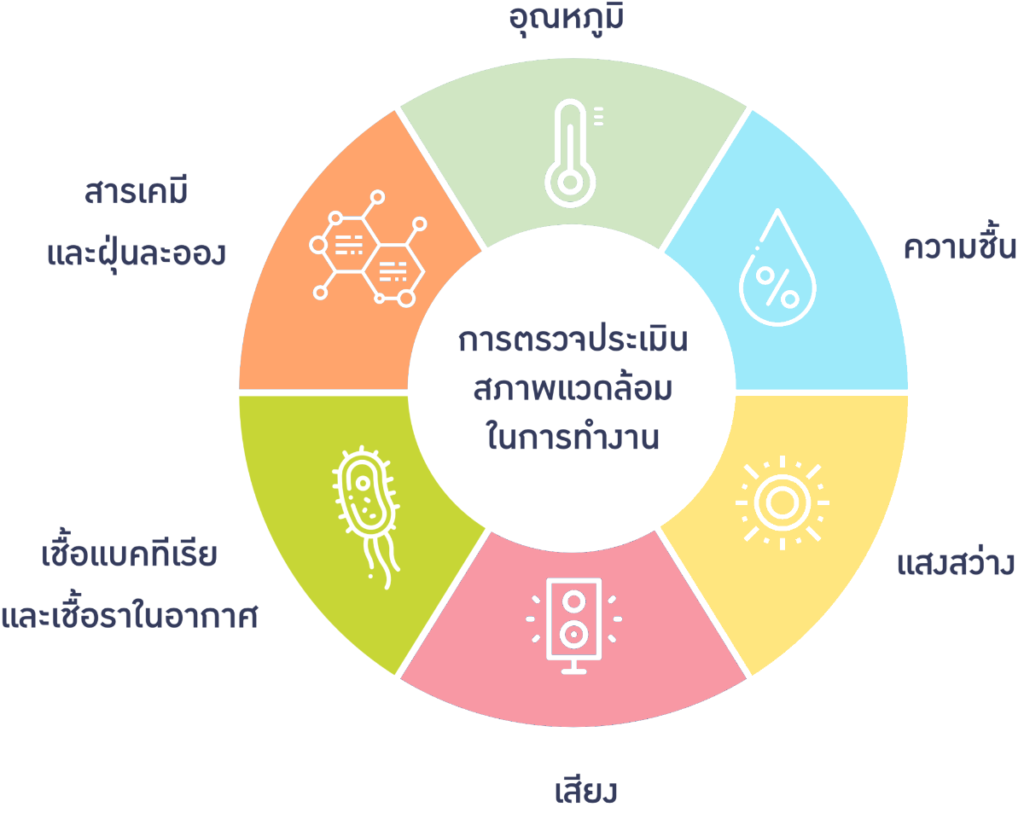

Occupational Environment Assessment

AOT determined the occupational environment assessment of employees and workers on a regular basis. The departments responsible for occupational health and safety and work environment each airport must inspect and monitor the work environment to be consistent with the related laws and standards on occupational health, safety and work environment, covering indoor environment quality, e.g., temperature, humidity, light, noise, dust particle, and airborne bacteria and fungi in the air.

Medical Services

AOT provides medical clinics at every airport including the Head Office for preliminary treatments for employees and operators in AOT’s premises in case of illness or injury while working. AOT also provides employee’s annual medical check-up and medical benefits to ensure of good health and well-being of employees.

Training for Specific High-Risk Workers

According to AOT's requirements, contractors who work with specific risks must receive relevant trainings and/or high risk work licenses such as working with cranes and forklifts, working at height, working in a restricted area or an area relating to fuel or in a confined space, working with hazardous chemical or relating to a highly radioactive material or generating heat and sparks, such as cutting, welding, grinding, etc.

Safety for Contractors

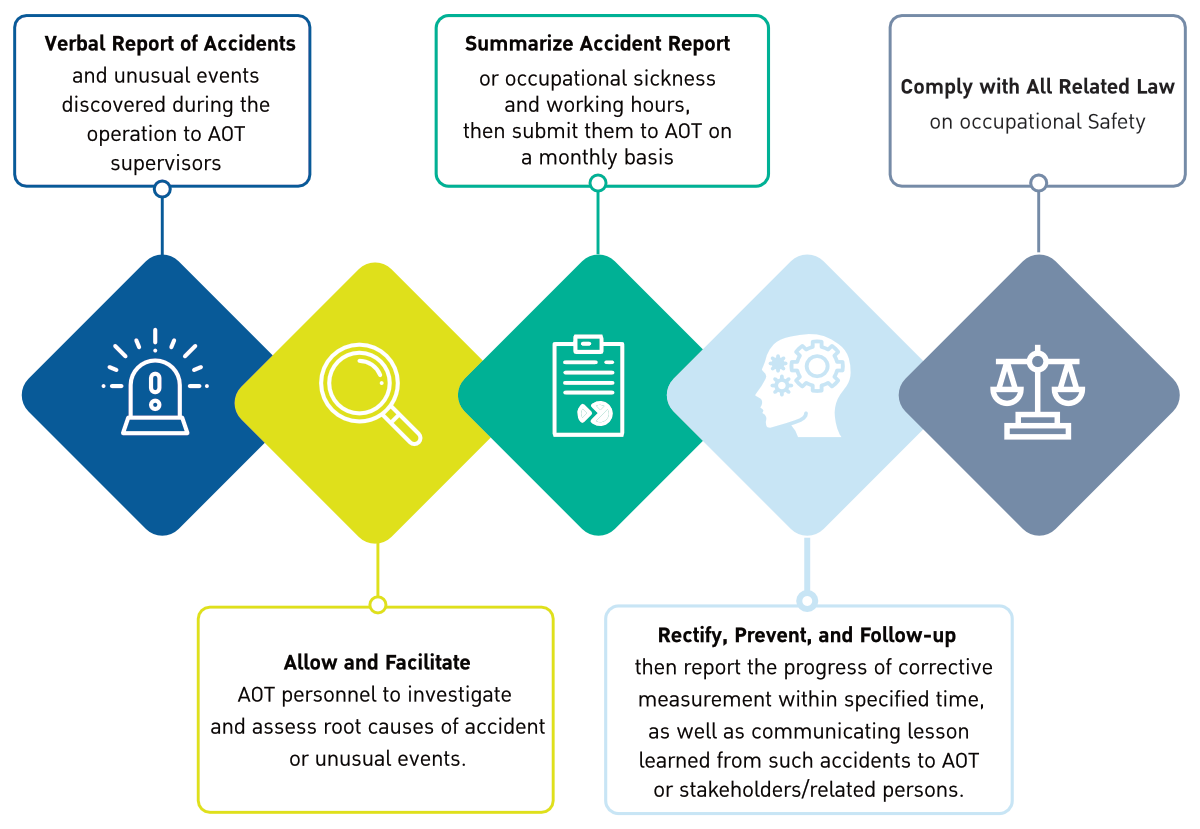

AOT has prepared and published regulations and manual on safety at work for the contractors to be used as complete and correct safe operating guidelines, as required by law, which controls risk that may occur due to contractors’ operations and create positive safety outcomes for all staff and external contractors working in AOT's premises. The contractor's operating terms and conditions in compliance with occupational health and safety requirements and suppliers' sustainable practices have already been clearly stated in the Term of Reference (TOR) and communicated with workers to follow the safety standards each time before starting work. At present, AOT requires contractors to report safety statistics and performance on a monthly basis through the information system regarding the management of safety information for contractors. The guidelines can be summarized as follows:

ดูรายละเอียดเพิ่มเติม

Promote a culture of Occupational Health and Safety

AOT promotes safety and supports a safety culture within the organization by organizing training and campaign programs. These include activities such as regular monthly safety inspections of each department's work areas, safety talks to encourage employees to discuss safety-related topics within their departments, and Safety Day events that raise awareness and engage employees in activities that communicate safety information at various booths, with rewards for participating employees and interested individuals.

These initiatives aim to provide safety knowledge to both new and current employees, in line with basic safety standards mandated by law and the International Civil Aviation Organization (ICAO). This includes fundamental airport safety and emergency plans, fire drills, and training in occupational health and safety management systems beyond legal requirements. Examples include training for operations in accordance with the international standard ISO 45001:2018 and training for supervisory staff to oversee contractors, among others.

Fire Fighting and Evacuation Fire Drills Project

Fire fighting and evacuation fire drills is a mandatory safety activity that AOT arranges every year in all of its airports and the Head Office, according to the Ministerial Regulation on the Standard for Administration and Management of Occupational Safety, Health and Environment in relation to Fire Prevention and Control B.E. 2555 (2012). This is to ensure that all employees have knowledge and understanding of how to act in emergency situation, while related officers and responsible persons can develop their management skills for dealing with a fire situation.

Accident Prevention Program for AOT Employees

AOT has implemented programs to promote accident prevention in the workplace, such as the Safety Day program. This initiative aims to raise awareness and encourage employee participation in activities that communicate safety information at various booths, with rewards for employees and individuals interested in participating.

Annual Fire Evacuation Drill B.E. 2566 (2023)

In 2023, AOT organized an annual fire evacuation drill for employees as required by law. This drill ensures compliance with the Ministerial Regulation on the Standards for Administration, Management, and Operations concerning Occupational Safety, Health, and Working Environment related to Fire Prevention and Suppression B.E. 2555 (2012).

Management Evaluation

AOT organizes an audit according to the Internal Audit on Safety and Occupational Health Management System, conducted by the Occupational Safety and Health Department together with a group of internal auditors from every department, who have been trained the auditor training courses, and external auditor from independent units in accordance with ISO 45001: 2018 standard. The safety agency reports the results of audit and accreditation on the Occupational Health and Safety Management Standards to senior management in order to review and define measures for further development of safety, occupational health and work environment operations and also discloses the performance to the public in AOT Sustainable Development Report.

Work-Related Injury Statistics for Employees and Staff

AOT compiles and maintains work safety statistics, including the Lost Time Injury Frequency Rate (LTIFR) and the Lost Time Injury Severity Rate (LTISR), as outlined by the American National Standards Institute (ANSI). These statistics are analyzed to identify the causes of problems and to develop risk reduction plans and preventive measures. The collected statistics are verified by a Certification Body according to the ISO 45001:2018 standard before the certification is granted.

- Lost Time Injury Frequency Rate (LTIFR) = (Number of injuries resulting in lost workdays x 1,000,000) / Total working hours

- Lost Time Injury Severity Rate (LTISR) = (Number of lost workdays due to injuries x 1,000,000) / Total working hours

Last updated: April, 25 2024